|

While the Mil Spec buffer tube looks similar the Commercial buffer tube, there are subtle difference between them. If your planning on building an AR or interested in upgrading your AR-15 stock, it is good to understand and know their differences. What is a buffer tube? A buffer tube, also known as a receiver extension tube, serves two purposes:

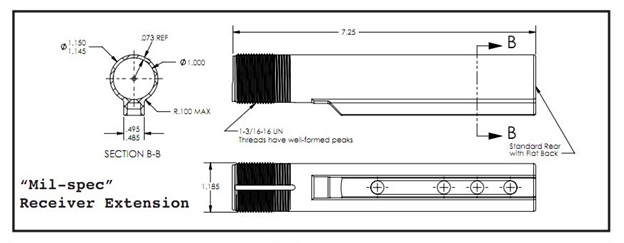

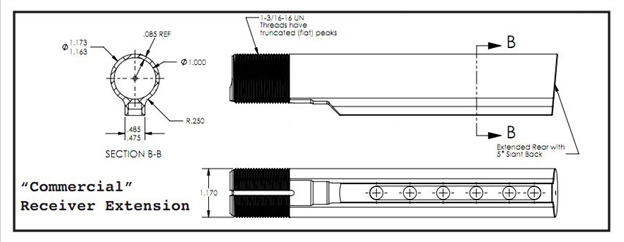

It is referred to as a “buffer tube” because it houses a large spring inside (called the action spring), and its weighted part known as the “recoil buffer.” There are many slight differences in buffer tubes on the market, but the main difference is between the Mil Spec and Commercial. Mil-Spec AR-15 Buffer Tube Military Specification or Mil-Spec are the standards in which the General Accountability Office (GAO) puts in place for defining requirements and standardized measurements of equipment used by the military. These are established to guarantee interoperability, commonality and reliability for each purchased part used for the military. As the name suggests, this buffer tube meet as all the requirements of the GAO. The Mil-Spec buffer tube, on its threads at the front are a larger diameter than the rest of the tube itself. When manufactured, a large tube is used and is threaded on a lathe as normal. After, the rest of the tube is milled down to the military specified diameter of 1.148”. This means that these tubes are forged, one-piece design and the threads are rolled. Commercial Spec AR-15 Buffer Tube Unlike the Mil-Spec, the commercial style tubes begin with a tube that already matches the final tube diameter. Threads are “cut” into the front end with a lathe just like threading any other threaded pipe. End caps are usually welded on, so commercial tubes are actually made up of two pieces of material. The outside diameter of the tube is 1.168”*.

*Manufacturers can change parts on their rifles throughout the years, so please double check your diameter and confirm the back-end shape before replacing the buffer tube so that it will fit your stock. How can I tell which size buffer tube I have or need? The best way to know is to measure using a micrometer, and measuring the diameter of the tube, and match the tube to the stock. Remember, the mil-spec tube should measure around 1.146” and a commercial tube around 1.17”. But why are there two different kinds? It all comes down to money. As the mil-spec tubes were the original design, the manufacturing processes of commercial spec buffer tubes were a lower cost. When the M4 was first introduced as military weapon, there was only the mil-spec type of tube. But as the M4-pattern rifles moved to civilians, companies realized that they would make the tube cheaper by how they made it. By making the commercial tube a touch larger in diameter the threads could be cut in vs the mil-spec where the threads are rolled in. So, the million-dollar question: Which one is better? There is no answer here. Neither one is better than the other. There is no scientific evidence supporting that one standard is noticeably “better” than the other on strength, performance, etc. At Black Bag Resources along with many other similar companies, recommend the mil-spec buffer tube. Why? Even though it costs a little more, there are more options for aftermarket stock upgrades. At BBR we recommend the Timber Creek Mil-Spec Buffer Tube. It is compatible with stocks from a wide range of manufactures. It is made up of aircraft grade aluminum in the standard Mil-Spec size and comes in a variety of colors to complement the rest of your custom build or change out.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Black Bag Resources Blog

News, projects, products, and tips from the owner. Archives

September 2022

Categories

All

|

RSS Feed

RSS Feed